About Me

As a dedicated teacher and researcher, my primary goal is to create a dynamic learning environment that nurtures the development of skilled professionals through classroom instruction, laboratory experiments, industrial training, and research projects. I have always believed that teaching and research are two sides of the same coin in academia, a belief that has guided my career. Inspired by passionate teachers throughout my education, I strive to instill the same dedication in my students. My journey in academics began at the Indian Institute of Technology in 2000, where I benefited from mentors like Prof. N. B. Ballal, whose guidance helped me grow as an academician. I prioritize quantitative aspects in metallurgical engineering, using innovative teaching methods to enhance student learning, and have received multiple teaching excellence awards based on student feedback

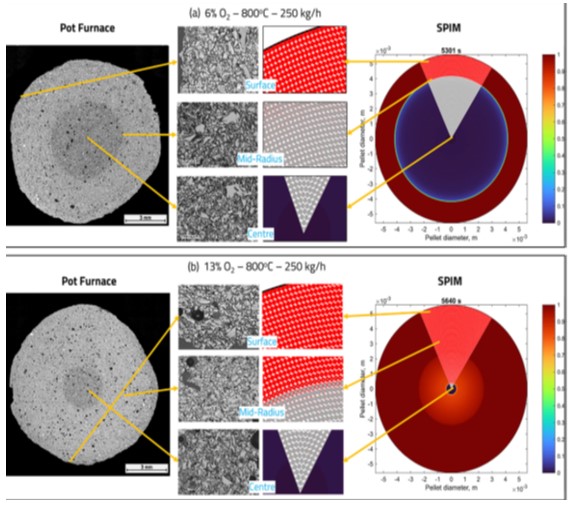

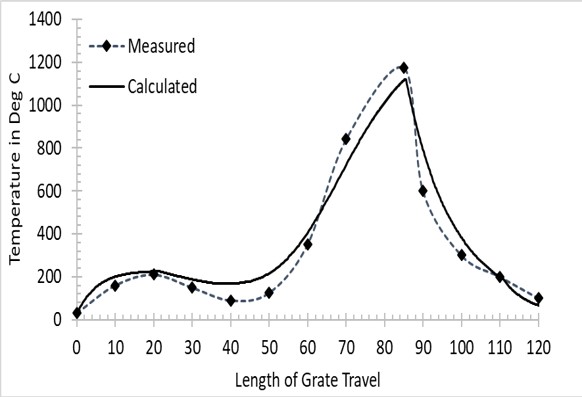

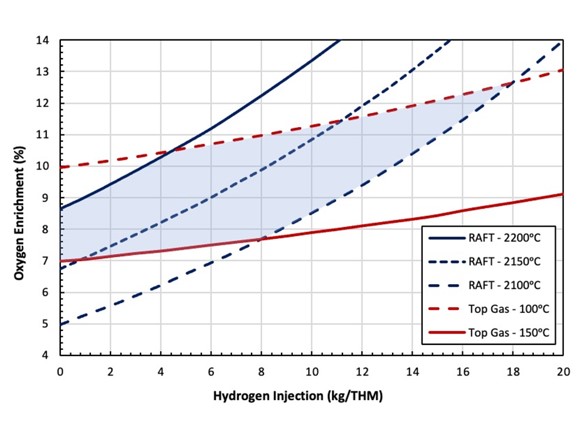

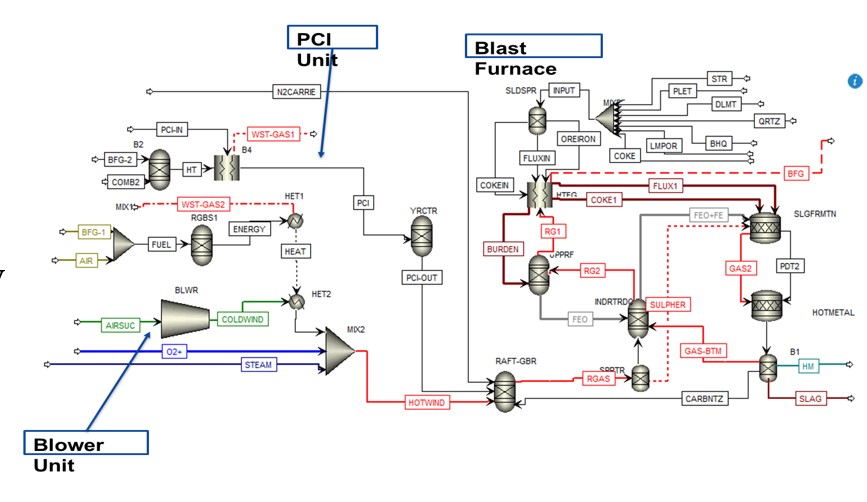

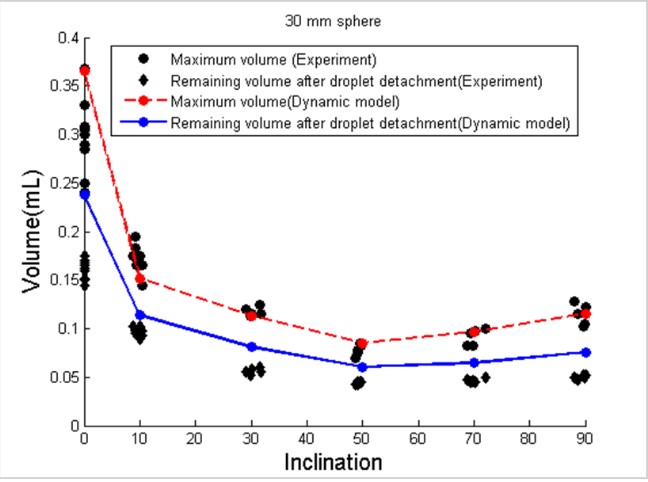

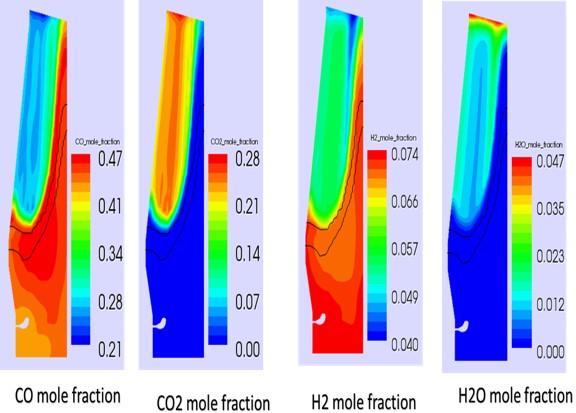

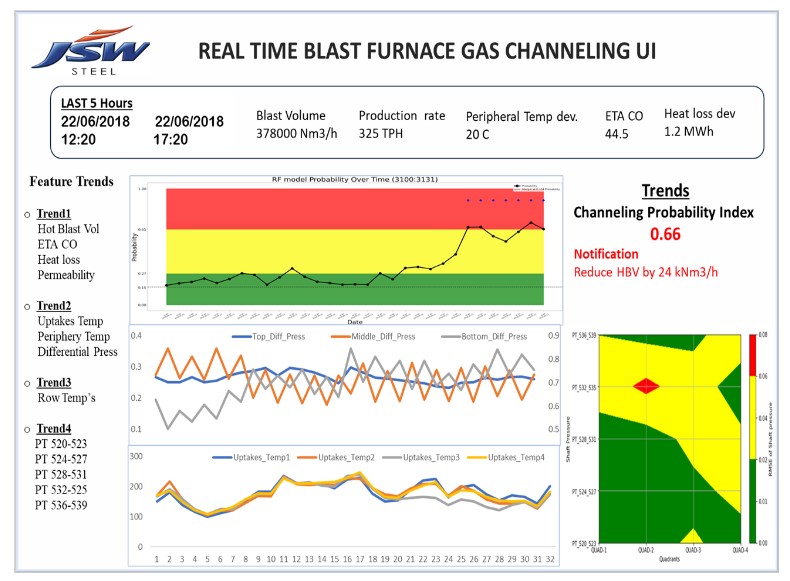

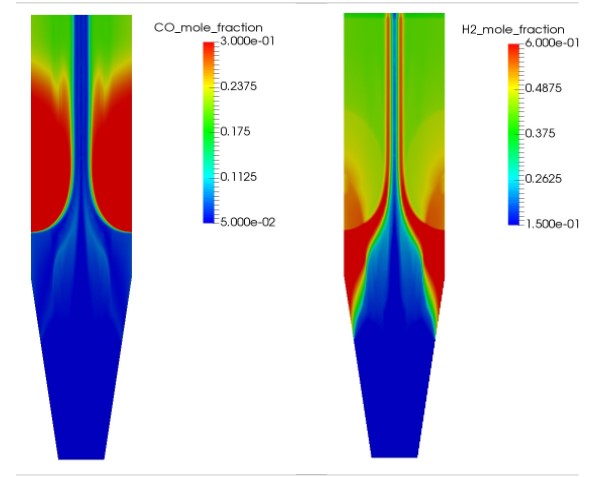

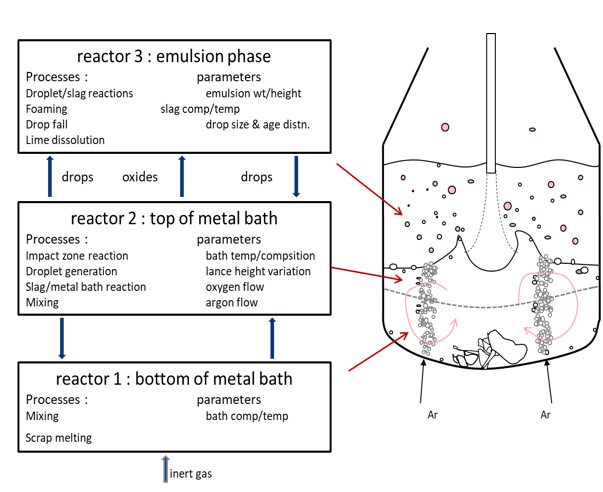

In research, I have pursued significant projects such as the development of a comprehensive two-dimensional blast furnace simulator (BlaSIM) with the support of numerous master students and collaborators, and the creation of the Single Pellet Induration Model (SPIM) during my tenure as the LKAB Chair Professor in Sweden. My efforts extend to other crucial steel-making processes, including BOF, ladle operations, and continuous casting, integrating experimental knowledge for quantitative predictions. Additionally, I have been instrumental in establishing the Centre of Excellence in Steel Technology (CoEST) at IIT Bombay, fostering industry collaborations and creating a vibrant steel technology program. These efforts have culminated in numerous national and international publications, reflecting the scientific contributions and collaborative enthusiasm of my research endeavors.I prioritize quantitative aspects in metallurgical engineering and utilize innovative teaching methods to enhance learning. My commitment has earned multiple teaching excellence awards. I have played a significant role in developing the M.Tech program in Steel Technology, aiming to elevate the quality of professionals in the steel industry. Through various courses and workshops, I focus on improving the curriculum's analytical and quantitative content, ensuring it meets the evolving demands of the industry