Green Steelmaking

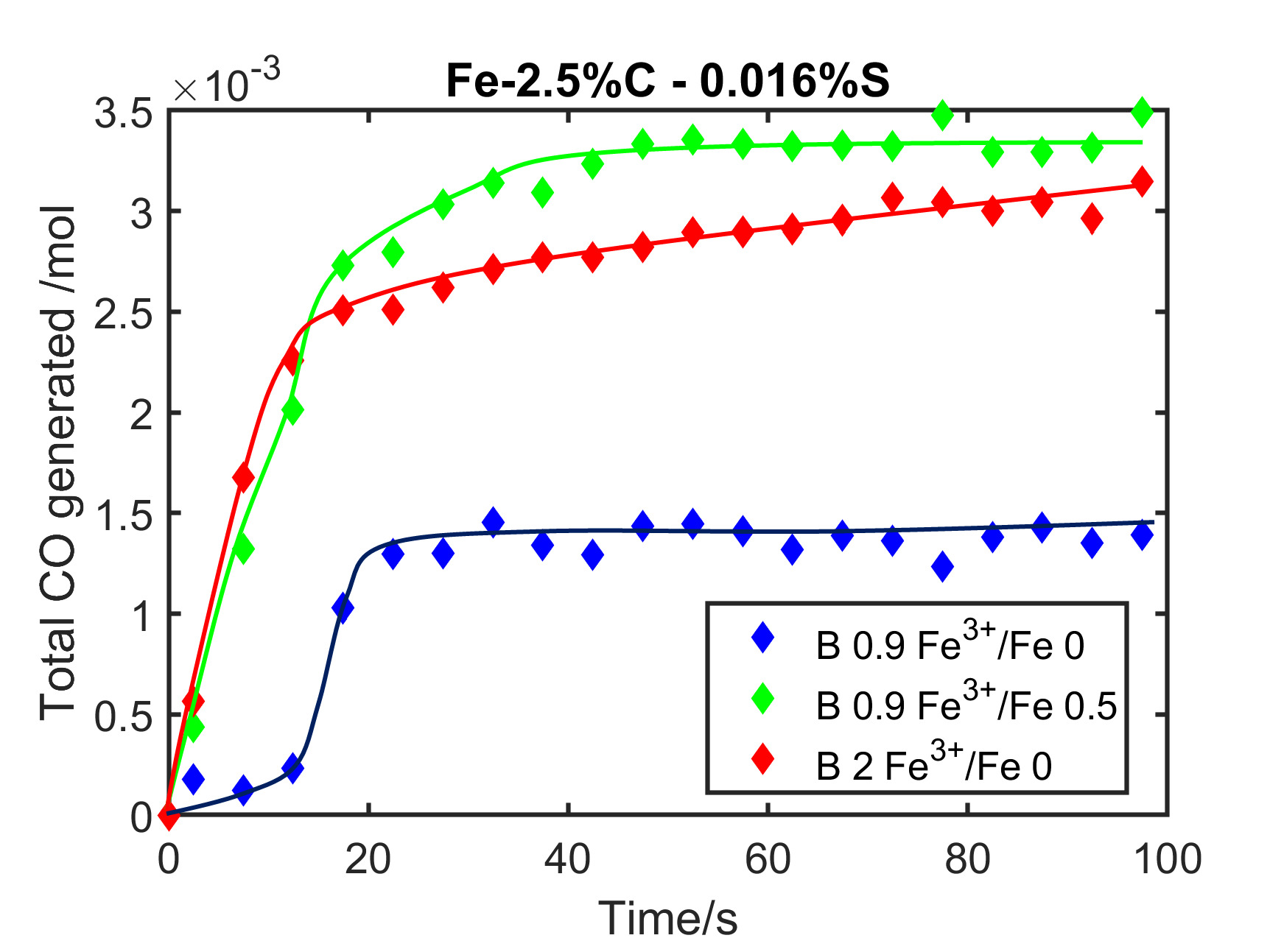

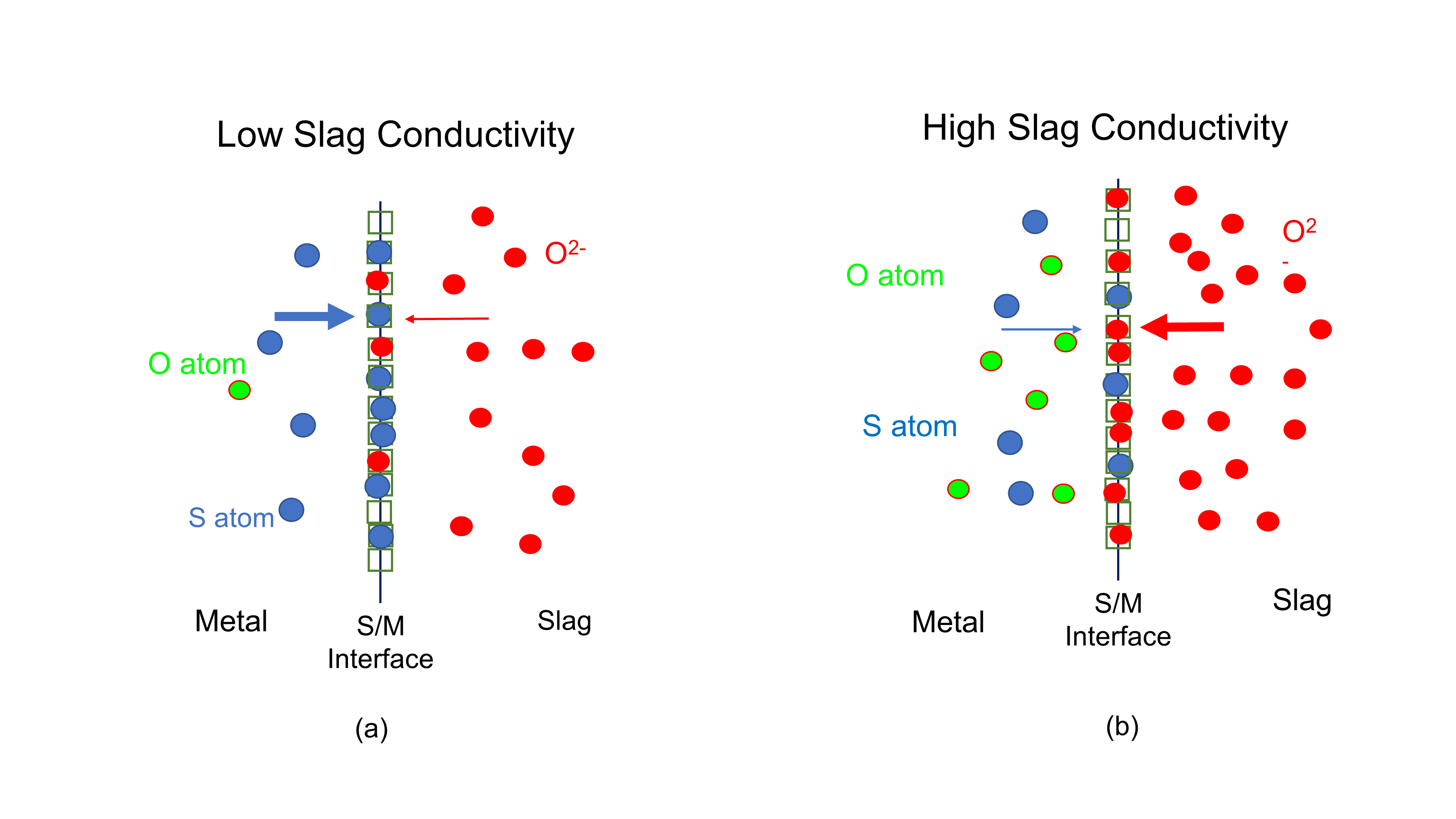

The steel industry is one of the largest contributors to the global emission of CO2 (8%). To decarbonize the steel industry, green hydrogen-based reduction followed by steelmaking is being explored as one of the potential alternate routes. However, there are several challenges in transitioning this route. In our research group, we are currently exploring some of the issues related to this new route. Previously, the effect of electronic and ionic conductivity on decarburization kinetics was investigated through high-temperature slag/metal droplet experiments. The effect of surface active elements on refining was also explored for slag/metal reactions.

Recycling of Urban Ores

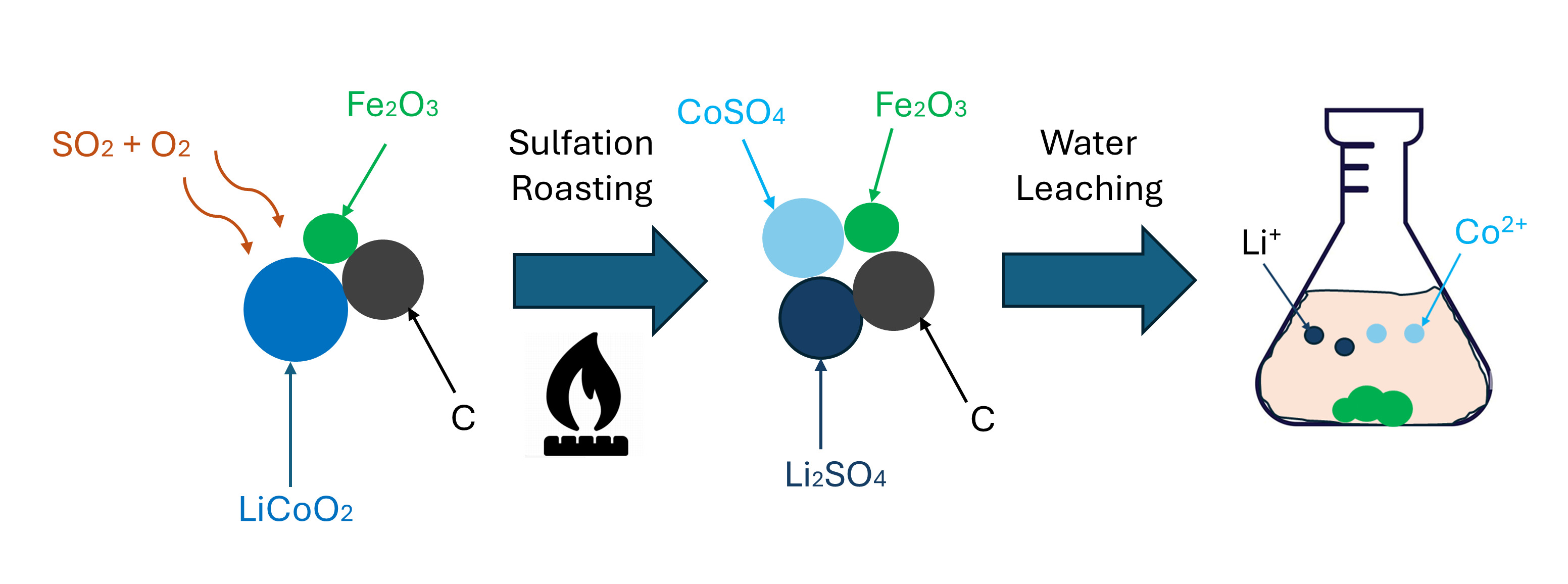

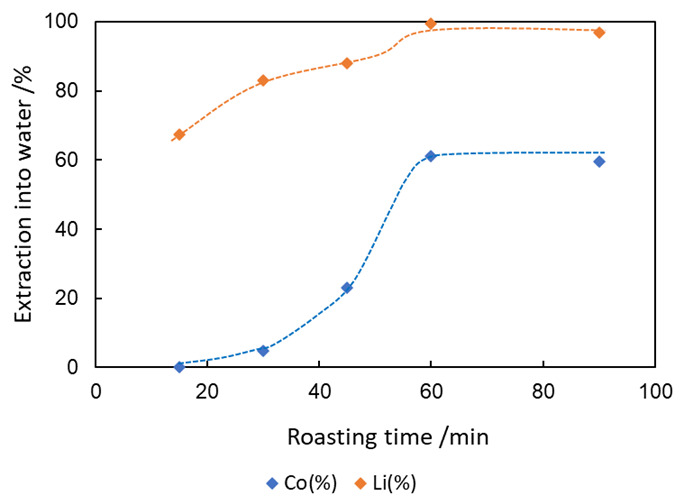

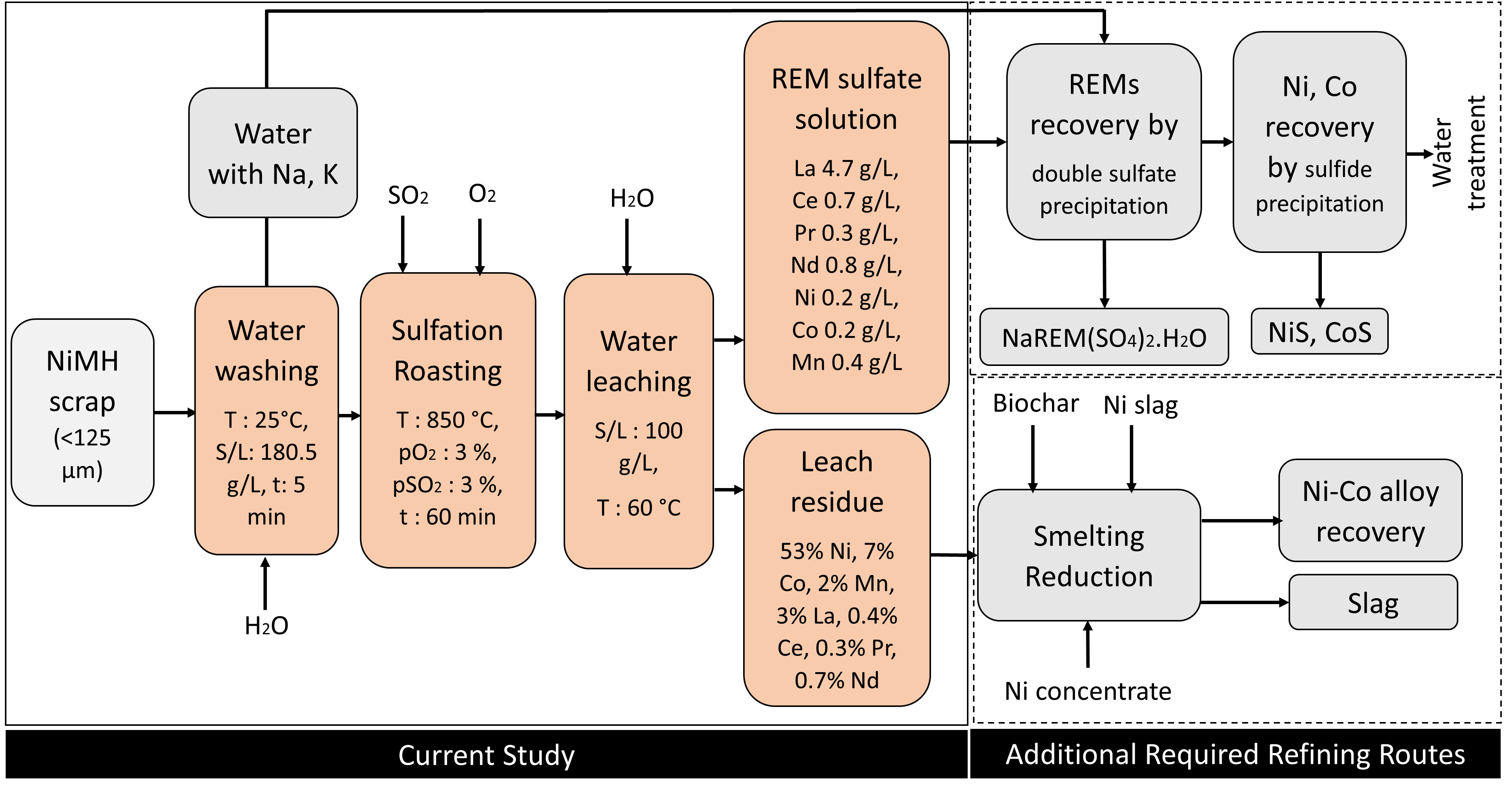

The urban ores such as waste PCB, spent batteries, waste solar cells, etc. contain significant quantities of valuable metals - Li, Co, Cu, Ni, rare earth elements, etc. These metals have been identified as ‘Critical Minerals’ by the ‘Ministry of Mines (Govt of India)’ due to their high demand and poor availability. Recycling these urban ores has become essential. Previously, some work has been done on the extraction of Li, co from spent Li-ion battery waste and rare earth metal extraction from NiMH battery waste. Our group is looking into the extraction of valuable metals from various secondary ores through a combination of various pyro/hydrometallurgical unit processes.

Process Modeling

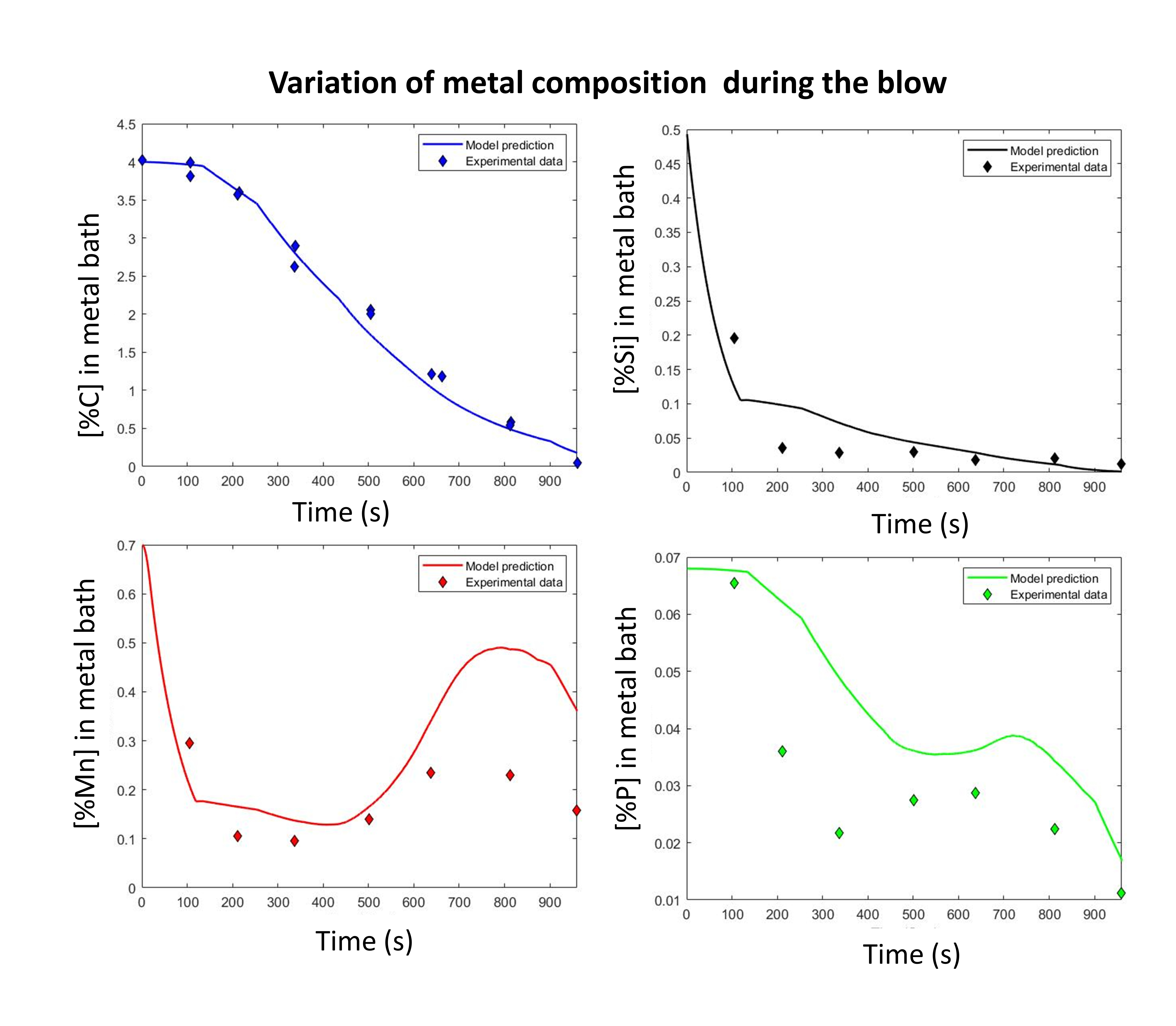

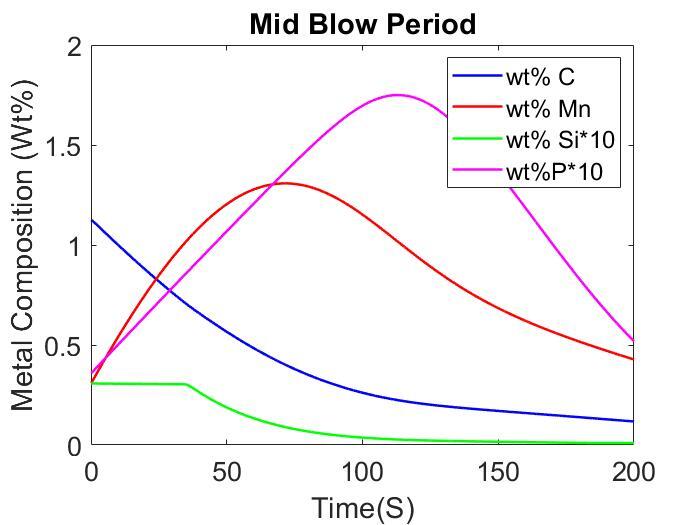

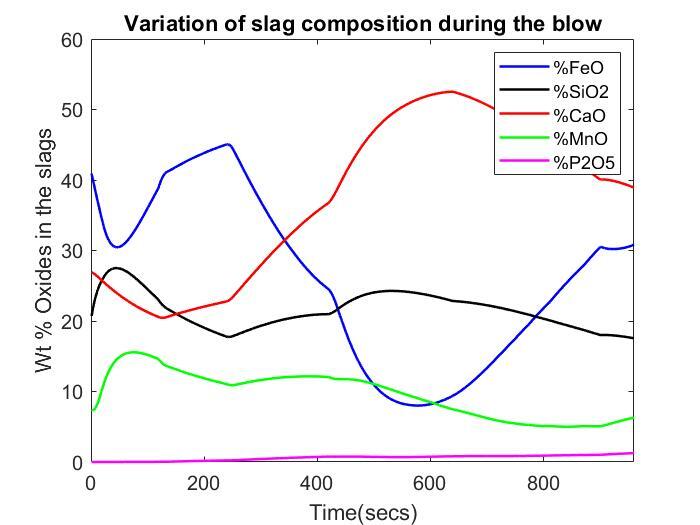

Developing dynamic process models considering the mass transfer and heat transfer principles and predicting the composition, and temperature profile with time is one of the areas of our interest. Previously, a dynamic model was developed for the LD converter steelmaking process, which was able to capture the refining kinetics in the emulsion zone and predict the metal and slag bath composition evolution, especially ‘P reversion’ and ‘Mn reversion’ with oxygen blowing. Currently, some work is ongoing in developing a dynamic model for the EAF steelmaking process.